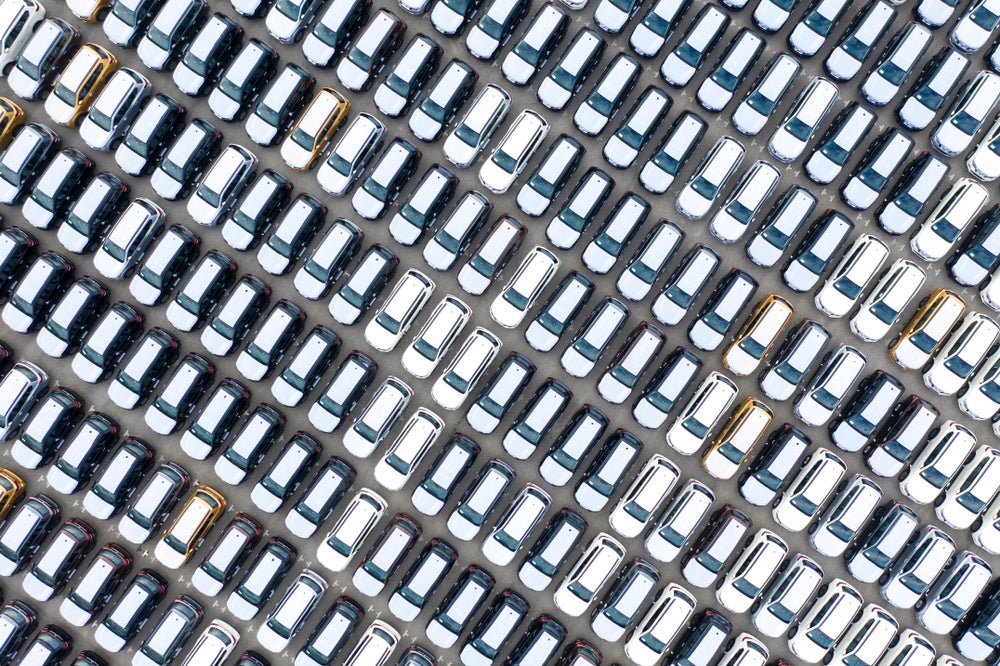

Toyota is to operate its Japanese

plants at half-normal volumes for a month from early May, following

parts shortages in the aftermath of last month’s earthquake and

tsunami.

The firm’s major overseas factories

have also been affected by the disruption, with production being

suspended at five European plants from late April to early May.

Access deeper industry intelligence

Experience unmatched clarity with a single platform that combines unique data, AI, and human expertise.

The company had a non-production

day on 21 April at its vehicle factory in Burnaston, Derbyshire,

and engine plant in Deeside, north Wales, affecting 3,000

workers.

The plants will also close for the

Easter weekend, the Royal Wedding weekend, and the three days

between.

Meanwhile Honda has been forced to

halve production at its UK plant in Swindon, while the Nissan

factory in Sunderland halted production for three days in

mid-April.

Nissan has already suffered a

production loss of 55,000 cars in Japan.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataAlthough industry optimists are

hoping normal production will be resumed by the end of May, there

remains the possibility of future difficulties with the supply

chain that might have consequences for some dealers.

Broker First Vehicle Leasing (FVL)

speculated on the options for dealers knowing that stock is going

to be hard to come by.

FVL said: “Will you: A, keep

selling vehicles as you currently are and hope the supply chain

improves?

“B, sell fewer vehicles to aid

supply availability – thus making less money?

“Or C, remove special offers and

deals and sell all vehicles at full price where possible, promoting

pre-registered and used stock to customers who need a vehicle

quickly?

“It doesn’t take a genius to figure that one out.”