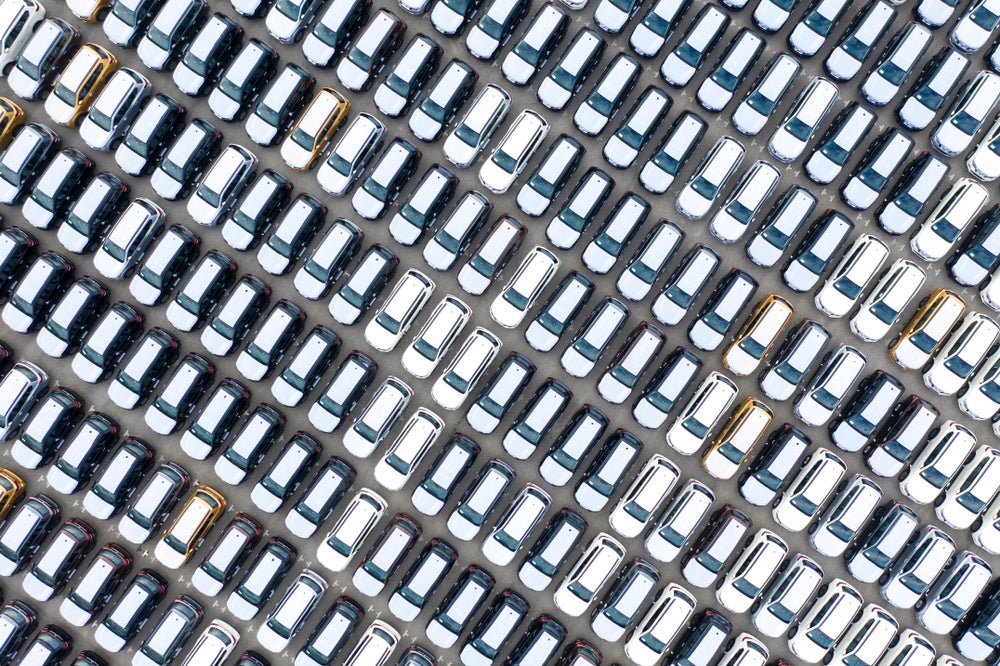

The European automotive industry is preparing for a crucial vote in the European Parliament on the new End-of-Life Vehicles Regulation (ELVR), a decision that could mandate higher recycled steel content in new cars. While environmental groups are pushing for ambitious, legally binding targets, some industry players are resistant, creating a tense standoff with significant implications for supply chains and green credentials.

The vote is scheduled to take place during the September 8–11 plenary session in Strasbourg. It follows a July vote by Parliament committees that established a negotiating position, which includes a call for a feasibility study on recycled steel targets.

Access deeper industry intelligence

Experience unmatched clarity with a single platform that combines unique data, AI, and human expertise.

T&E calls for tougher targets

The environmental organisation Transport & Environment (T&E) is a key advocate for stricter mandates. Citing its own research, T&E points out that currently only around 10% of the steel in new cars comes from recycling, compared to over 60% in the construction sector. T&E argues this reliance on primary steel production from coal-fired plants results in avoidable carbon emissions and a dependency on imported iron ore.

T&E’s position, supported by a feasibility study from the Öko-Institut, suggests that setting targets of 30% recycled content by 2030 and 40% by 2035 is both technically and economically viable. To achieve this, T&E is pushing for specific dismantling requirements in the ELVR to remove copper-rich wiring harnesses before shredding, which would improve the quality of recycled steel to the high standard needed for automotive applications.

Winners and losers

The upcoming vote on mandatory recycled steel targets creates clear gains and risks for different industry stakeholders:

The status quo benefits manufacturers who have prioritised traditional vehicle production over fully integrated circular economy principles. As noted by the European Environmental Bureau (EEB), the auto industry has historically shown resistance to stringent circular economy rules. This is evidenced by past anti-recycling behaviour, with fines issued to some major manufacturers, including Volkswagen, Mercedes-Benz, and BMW. The EEB also suggests that historically weak legislation has prevented high-quality recycling and allowed for opaque end-of-life vehicle management.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataThe upcoming ELVR vote could disrupt these practices for companies that have not fully embraced circularity.

- Stellantis, despite having some circular economy initiatives, faces challenges in aligning its numerous brands across Europe and has previously voiced concerns over EU policy changes impacting its UK production. The vote could accelerate the need to standardise circular practices across its vast brand portfolio.

- Toyota, while actively increasing its focus on circularity, has been cited as a relative laggard in the shift to fully electric vehicles and integrated circular processes. The ELVR may force a more rapid pivot, particularly in Europe, to meet the design and material transparency requirements.

- Widespread industry resistance: A 2022 Bain & Company study found that the automotive sector as a whole was slow to adopt circular business models. Continued resistance to change risks leaving these companies unprepared for future regulations and the evolving market demand for sustainable products.

Traditional steel producers

The current situation favours primary steel producers who continue to operate using carbon-intensive methods. The ELVR’s potential recycled content mandate poses a direct threat to this business model.

- Thyssenkrupp and ArcelorMittal, major European steel giants, have faced scrutiny for their pace of investment in green steel production. T&E, among other groups, has voiced concerns about relying on government subsidies for this transition, arguing it is too slow to meet climate targets.

- Financial and environmental risk: Maintaining a primary steel focus exposes these companies to both financial risk (as demand for low-carbon steel increases) and regulatory risk under the EU’s Green Deal. The ELVR could accelerate their need for costly and challenging investment in EAF production or higher-quality scrap processing.

For these companies, the ELVR vote represents a pivotal moment, potentially forcing significant and expensive changes to their long-established operational models and supply chains.

EU and UK perspectives diverge

The outcome of the EU’s ELVR vote will have a limited direct impact on the UK due to its post-Brexit status.

- EU Perspective: The EU’s push for recycled steel targets is central to its broader Green Deal and Circular Economy initiatives. The legislation aims to increase producer responsibility, improve traceability, and raise recycling quality across the bloc to boost European competitiveness in sustainable manufacturing.

- UK Perspective: The UK continues to operate under its own ELV Regulations, which largely mirror the original EU Directive. These regulations focus on hazardous substance removal, producer take-back schemes, and recycling targets. While the UK industry is observing the EU’s more ambitious plans, it is not bound by them. However, for manufacturers exporting vehicles to the EU, meeting any new ELVR standards would be a commercial necessity.

What happens after the vote?

Following the plenary vote, the Parliament’s position will be used in three-way negotiations with the European Council and Commission. This is where the final details of the regulation will be hammered out, and the ambition of T&E’s recycled steel targets will be tested against industry and member state positions. The final legislation is expected to be adopted in 2026, but the September vote is a critical indicator of the direction the EU is heading.